The all-grain process I use for brewing beer at home is based on traditional methods, that have been used (and improved) for centuries. Only relatively recently have these methods been achievable with equipment designed for use at home.

The all-grain process I use for brewing beer at home is based on traditional methods, that have been used (and improved) for centuries. Only relatively recently have these methods been achievable with equipment designed for use at home.

What I present on this website are only the basics of the brewing process, there is much more information available, on other websites, and in the many books that have been written on this fascinating subject. What I present here is the minimal amount of knowledge that I have found is needed to produce a decent pint at home.

I have only ever used the ‘all-grain’ (or ‘full mash’) method of brewing, whereby the beer is brewed from all of the raw ingredients (malted barley, hops and yeast) – I believe that this will always achieve the best results at home (after a bit of a learning curve). There are two other methods for brewing: extract and partial mash. As the naming would suggest, the methods mainly differ in how the base of the beer is created, among other aspects.

Extract brewing simply uses extracts from the grains, whether in dry or liquid form, or a mixture of both, to form the base of the beer, known as ‘wort’. Extract brewing can also include the use of small quantities of grain to add depth to the beer.

Partial mash brewing involves the use of malt extract as well as grain. The combination of both provides increased possibilities in the creation of the flavour, body, appearance and overall quality of your beer.

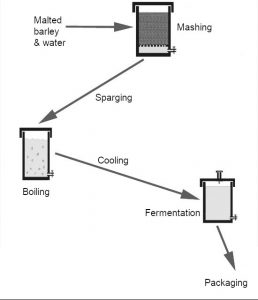

Brewing beer consists of eight main steps. I’ve detailed what I’ve learnt about each step in its own page:

- Cleaning & Sterilising – the first, and probably the most important step. Insufficient cleanliness can lead to the flavour of the beer being tainted, or, at worst, infected.

- Water treatment – tap water in the UK is generally not directly suitable for use as ‘liquor’ for mashing and sparging, and requires treatment with the addition of certain chemicals.

- Mashing – crushed malted barley (the ‘grist’) and other adjuncts are mashed with hot water (the ‘liquor’) and left for a period of time at a constant temperature.

- Sparging – rinses out all the sugars produced during the mash into the boiler.

- Boiling – the hot wort is brought to the boil and the hops are added.

- Cooling – the wort now needs to be cooled as quickly as possible, to avoid any infection occurring.

- Fermentation – the wort is now fermented into alcoholic beer, by the action of that amazing stuff YEAST.

- Packaging, conditioning & carbonation – finally the beer should be packaged into a keg or bottles, and left to ‘condition’ for a few weeks.

And I’ve also included a page on the lessons that I’ve learnt along the way!